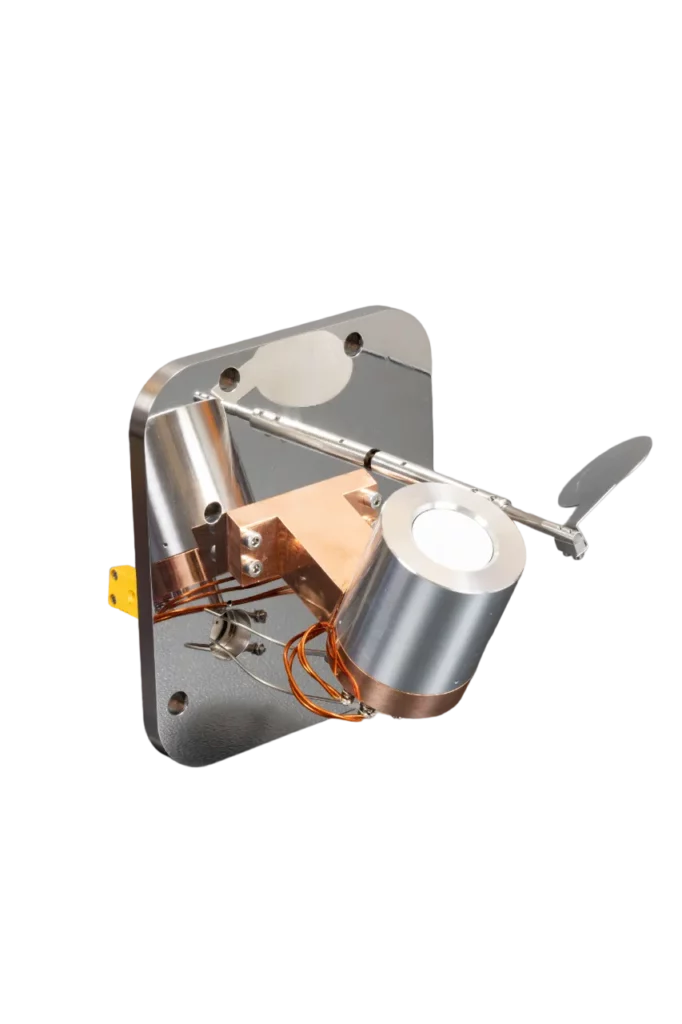

The ORCA low-temperature evaporation source employs active cooling of the crucible to ensure that the heating process is balanced by a strong opposing cooling process which results in excellent temperature stability and control.

The crucible is constructed from high thermal-conductivity material, ensuring no hot-spots arise which could distort the evaporation rate. Optionally, alumina or graphite liners may be employed. The crucible (complete with liner if fitted) is easily removed/swapped without the need for any tools, although this is often not necessary since access to the source in order to refill the crucible is rapid and simple.

The K-type thermocouple is inserted into the body of the crucible, giving much more accurate readings than typical touch-contact arrangements. The source is supplied with a power unit coupled with a PID controller tuned to low-temperature operation.

The source may be used in conjunction with sputter sources, e-beam sources, thermal sources and others. Thermal cross-talk is kept to a minimum through the cooled shielding cap. The ORCA is also perfectly paired with our temperature gradient sample stage allowing precise temperature control of the substrate.

Deposition Technique

The evaporation of materials at low temperature (50-600oC) requires specialised sources which are specifically designed to operate in this range. Conventional evaporation sources are built in order to operate most efficiently at >1000oC which requires that conductive thermal losses are kept to a minimum. This has the consequence that the mechanism which allows accurate PID control relies almost entirely on radiative losses. At lower temperature, radiative losses are dramatically reduced and control loops in conventional cells suffer from overshoot and slow temperature change.

Technical specifications

| ORCA – Organic Evaporator | |

|---|---|

| Crucible | 15cc (5cc Optional) |

| Temperature Range | 50-600°C |

| Thermocouple Type | K-Type |

| Power supply | DC |

| Cooling | Water (min 0.5l/min) |