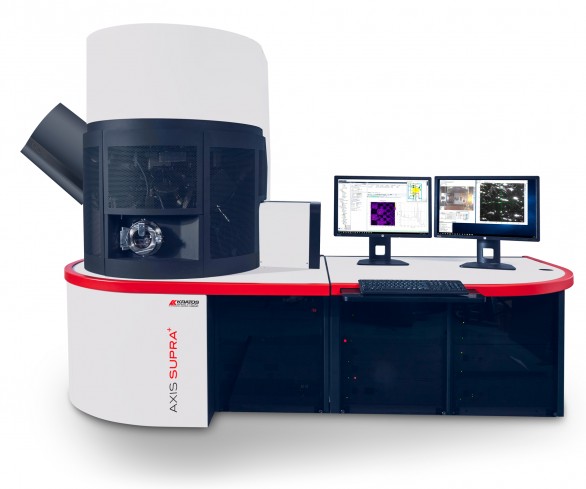

AXIS Supra+: XPS surface analysis instrument

Our next generation XPS, the AXIS Supra+, with enhanced performance over its predecessor, combines market leading spectroscopic and imaging capabilities with unrivalled automation to ensure high sample throughput and ease of use. Unrivalled large area spectroscopic performance allows photoelectron spectra to be acquired. Fast, high spatial resolution XPS imaging reveals the lateral distribution of surface chemistry and aids further characterisation with selected area analysis.

Improved Performance

The AXIS Supra+ is set apart from any other spectrometer by complete automation through computer control of sample handling and instrument parameters. Unattended sample holder transfer and exchange during analysis is achieved through coordination of the Flexi-lock sample magazine and sample analysis chamber autostage.

ESCApe integrated acquisition and processing software allows the AXIS Supra+ to perform to its maximum capability and provides an easy interface with the spectrometer.

Capabilities of the AXIS Supra+

Large area, high sensitivity XPS

The AXIS Supra+ is optimised for chemical state X-ray photoelectron spectroscopy. Efficient collection of photoelectrons combined with high transmission electron optics ensures unrivalled sensitivity and resolution at large analysis areas. As well as conventional scanned acquisition, spectra may be acquired in fast, unscanned snap-shot mode in less than a second making use of the 128 channel Delay-Line Detector (DLD).

Key capabilities include:

- Easy detection of light elements

- Excellent signal-to-noise, even at low concentrations

- Fast data acquisition

- Scanned or snap-shot spectral acquisition modes.

High energy resolution

The fundamental requirement of any spectrometer is the best possible energy resolution. High energy resolution, where the spectrometer does not contribute to the broadening of the photoemission peaks, is critical for the accurate measurement of small chemical shifts. The AXIS Supra+ has a large 500 mm Rowland circle monochromated Al Kα X-ray source and optimised electron optics ensuring excellent chemical resolution.

Advantages of high spectral energy resolution include:

- Unambiguous identification of chemical shifts

- Guaranteed energy resolution on insulating and conducting samples.

Fast parallel imaging

The lateral distribution of elements or chemistry at the surface is measured by XPS imaging. The AXIS Supra+ acquires fast, high spatial resolution parallel images. Parallel image acquisition has the advantage that it is significantly faster and achieves higher spatial resolution than the more conventional rastered beam approach. Parallel imaging may also be combined with stage movements to acquire a ‘stitched’ image, capable of generating images over several millimetres with spatial resolution of several microns.

Capabilities provided by parallel imaging include:

- Ultimate spatial resolution of 1 micron at the highest magnification.

- High energy resolution, chemical state imaging.

- Quantitative imaging – the unique spherical mirror analyser and delay-line detector can provide quantitative chemical state images.

- Spectromicroscopy – easy acquisition of spectra from image datasets providing a spectrum at each pixel.

Versatile ESCApe software for acquisition and processing

ESCApe has been developed to make User interaction with the spectrometer as simple as possible, integrating acquisition and processing to fully exploit automation of the hardware. An example of this is the group array analysis capability within ESCApe. This functionality allows the User to drag an area across a sample and define an array of analysis points, from which spectra are acquired. Automated peak identification and quantification allows easy generation of a colour concentration map of identified elements over the sample surface.

Unrivalled instrument automation

The AXIS Supra+ has complete automation of sample handling which sets it apart from any other spectrometer. Auto sample exchange at the end of an experiment allows continuous operation. Unprecedented levels of automation extend to routine maintenance aspects such as computer controlled bake-out and subsequent degassing of filaments.

Automation also includes the X-ray source and monochromator mirror so that calibration and switching between Al Kα and optional Ag Lα excitation sources is completely computer controlled. Furthermore, continued optimised performance is ensured by the motorised multi-position anode.

High throughput sample handling – typical work flow

To guarantee high sample throughput, up to 3 sample holders may be placed on the Flexi-lock sample magazine. An optical image is acquired of each sample holder from which the sample analysis positions are identified during the automated ‘pump’ cycle. An acquisition method is chosen defining all requirements for the data acquisition. A method may define simple spectroscopy or more complex experiments such as sputter depth profiling or angle-resolved XPS. Subsequent analysis from samples on different sample holders can be added to the analysis queue with the automated sample handling system exchanging the sample holder to progress through the analysis queue.

Key attributes of AXIS Supra+ automated sample handling:

- Automated, unattended sample holder exchange.

- High throughput, rapid sample analysis

- Ideal for a multi-User environment

- Sample mounting area up to 7200 mm2 (2400 mm2 x3 sample holders) with maximum sample thickness 19 mm (when using dual height sample holder).

Configuration options

The AXIS Supra+ can be configured with the Minibeam 4, high flux Ar+ monatomic ion source. The ion source is fully integrated into the ESCApe acquisition software for sputter cleaning or depth profile experiments. Gas handling is fully automated for sputter profiling and includes pump/purge sequences to facilitate changing from Helium gas for ion scattering spectroscopy (ISS). The Minibeam 4 ion source operates with continuously variable beam energies between 500 eV and 4 keV. The design produces a high ion flux at low energy for improve interface resolution whilst retaining a high sputter rate.

The Minibeam 6 is a multi-mode ion source which can operate in Arn+ cluster mode and Ar+/He+ monatomic ion mode as required. Recent development of gas cluster ion sources has opened up the possibility of depth profiling organic materials with retention of chemistry throughout the profile. Depth profiles through complex multi-layer materials such as organic LEDs and flexible electronic devices are now possible with Arn+ cluster ions. A unique capability of the Minibeam 6 to generate 20 keV Arn+ cluster ions has allowed the successful etching of inorganic materials, such as titanium dioxide, with significantly less ion induced chemical damage.

The GCIS may also be operated in monatomic Ar+ mode for depth profiling metals or inorganic materials and used with He, generation He+ primary ions for the optional technique of ion scattering spectrometry (ISS).

With growing interest in using higher energy X-ray excitation sources relative to the commonly used Al Kα (1486.6 eV) The AXIS Supra+ can be configured with a dual Al Kα / Ag Lα (2984.2 eV) monochromatic X-ray source. One significant advantage of using higher energy photons is the ability to excite photoelectrons from higher binding energy core-levels. It is also the case that, with increased kinetic energy of core level electrons, the information depth also increases allowing greater sampling depth relative to conventional Al Kα. This is demonstrated by the increase in the information depth for Si 2p excited by Al Kα and Ag Lα which is 7 nm and 13 nm respectively.

As the Al Kα/Ag Lα dual X-ray source uses the same monochromator mirror this is a very cost effective way to add a higher photon energy source to the XPS instrument.

Additional techniques can be added to the AXIS Supra+ which are coincident with the XPS analysis position giving complementary insight to the sample. Importantly, addition of these techniques does not compromise the market leading XPS performance.

Optional excitation sources include:

- Achromatic Al/Mg X-ray source

- New and improved Helium discharge lamp for Ultraviolet Photoemission Spectroscopy (UPS)

- High energy Ag Lα monochromated X-ray source.

- Field-emission electron source for Auger Electron Spectroscopy (AES), Scanning Auger Mapping (SAM) and Secondary Eelectron Mmicroscopy (SEM)

- Inverse photoemission spectroscopy (IPES)

Sample preparation and surface modification options can be accommodated on the standard sample introduction chamber, also known as the Flexi-lock. These options include:

- Sample heat and cool

- Air sensitive sample transporter

- Broad spot ion source

- Crystal clever

- Glove box.

A third optional chamber can be configured to provide a dedicated UHV environment for surface science studies. A typical configuration equips this chamber with a manual stage and optional characterisation techniques including:;

- Low Energy Electron Diffraction (LEED)

- Inverse PhotoEemission Spectroscopy (IPES)

- Quadrupole Secondary Ion Mass Sspectrometry (SIMS)

The Surface Science Station (SSS) is a dedicated chamber interfaces directly with the sample analysis chamber and is designed to house a number of optional surface characterisation techniques including quadrupole secondary ion mass spectrometry (SIMS), low energy electron diffraction (LEED) or inverse photoemission electron spectroscopy (IPES). In-situ surface preparation and modification options may be added to the SSS including heating and cooling; thin film deposition; crystal cleavers, low pressure gas doser etc. The surface science station (SSS) has two experimental locations, the first at the centre of a cluster of flanges and a second at the end of the linear transfer mechanism. The SSS is typically configured with a manual stage for use with 15mm diameter stubs. Up to 3 sample stubs may be stored in the SSS.

The SSS is separated from the sample analysis chamber by an automatic gate valve controlled by the ESCApe data-system. The operation of the valve is interlocked with vacuum and position of the linear transfer mechanism.

The high temperature reaction cell is a dedicated facility that interfaces directly with the analysis chamber. In the cell it is possible to study catalitic reactiors at high temperature and high pressure. The sample can be transferred to and from the analysis chamber without expesing it to the atmosphere. The specifications are the following ones:

- Atmospheric pressure to 10 bar: room temperature to 1000 ̊C

- Atmospheric pressure to 20 bar: room temperature to 800 ̊C

- Fused quartz reaction chamber, Quartz sample holder

- Usual gases: H2, O2, H2O, CO2, CH4

- PID controller temperature with optional software interface

- Gas handling system

- Water and compressed air cooling. Temperature interlock to prevent

overheating