The HEX Series of thin film deposition systems provides a versatile range of deposition options for your research and implementation applications. To get started, you’re welcome to purchase the base model and upgrade to higher-level components to suit your needs as necessary. These upgrades are modular and simple to install, which reduces system downtime and installation costs.

The HEX Series includes the benchtop HEX and the larger HEX-L Systems. (See “HEX vs HEX-L page).

The benchtop HEX model comes with an 80 l/s pump that allows for base vacuums up to 8×10-7 mbar and allows for sample sizes up to 100 mm. The system also comes with a multi-sample holder that can accommodate several smaller samples simultaneously. The system contains many upgrade options, including a 300 l/s pump that achieves a base vacuum of 4×10-7 mbar.

Users may also opt for a larger HEX-L chamber with space for sample sizes up to 150 mm, or multiple smaller samples.

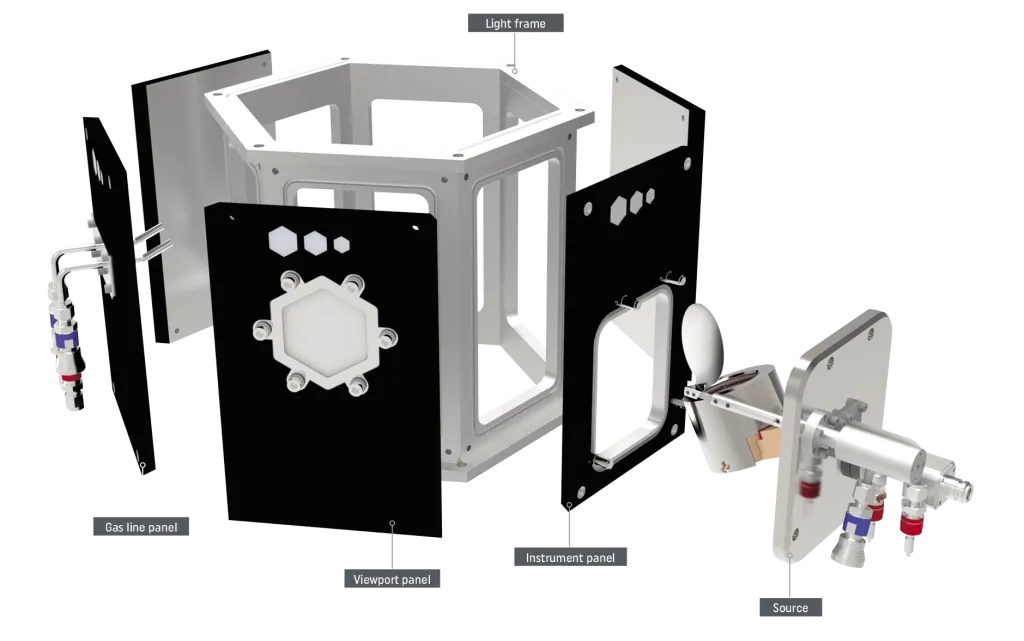

Modular Design for Rapid Re-Configuration

The HEX system consists of a six-sided aluminium-framed high-vacuum chamber that is lightweight yet rigid enough for most physical vapour deposition applications. The hexagonal structure supports six modular panels, including:

- Blank panel

- Viewport panel

- Deposition source panel

- PLD instrument process control panel including mass flow controllers and thickness control

- QCM panel for in-situ monitoring

The design uses standardised fittings, including Hamlet quick connects for the gas and water connections and wing nuts for sample stage and component attachments. This standardisation makes it simple to switch out panels and adjust the system to a particular application. The modular design also makes maintenance and reconfiguration faster and more efficient.

Designed With Research and Development in Mind

The HEX Series are ideal for research and development due to their modular nature. All essential elements are accessible, allowing testing of various components and thorough exploration of the processes involved in several thin-film deposition techniques, including:

- Sample preparation for surface analysis

- Sputtering

- Thermal evaporation

- Organic physical vapour deposition

Supported methodologies in the base model include:

- Metal and photoresist lift-off process

- EM sample preparation

- New coating research and development

- Magnetron sputtering deposition optimisation

Should your use case require additional functionality, the HEX system contains many other modules that expand the scope of the system for most thin film deposition processes.