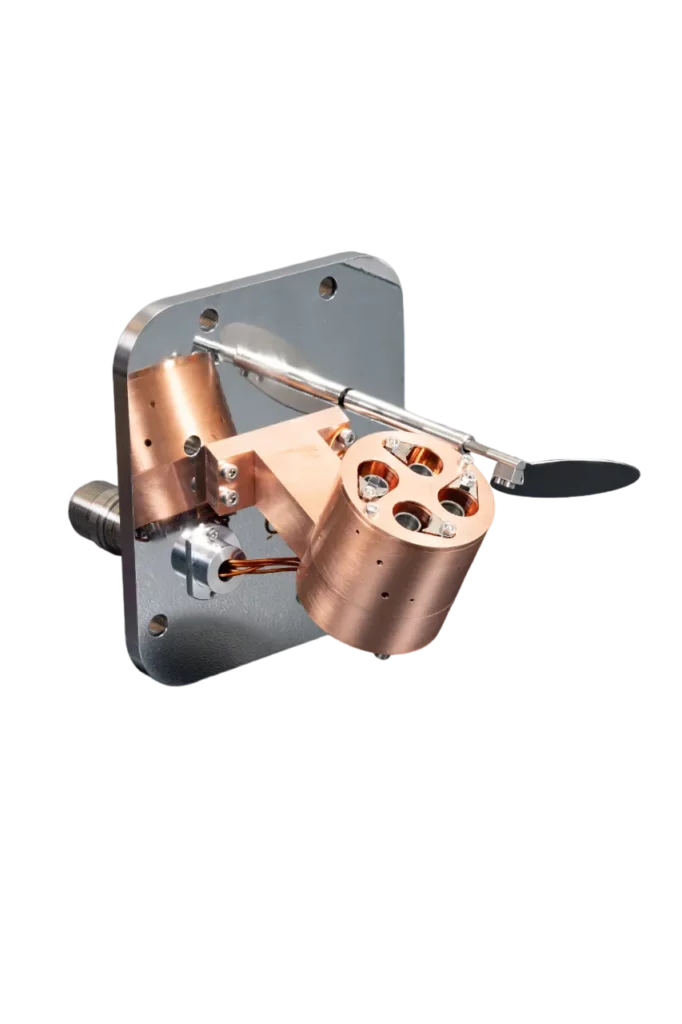

The TAU E-Beam evaporation source is a ‘mini’ source, meaning that it doesn’t use the beam-bending magnets found in other, larger electron beam evaporation sources. The TAU produces a high voltage at the target material while using the low voltage at the tungsten emission filament to produce a direct heating and evaporative effect.

One of the most significant concerns with the e-beam evaporation process is the heat generated during the vaporisation stage. The TAU uses an enclosed head that reduces the thermal load in the vacuum chamber, allowing for coating at relatively low substrate temperatures. This reduced thermal energy makes the TAU a useful tool in lift-off processes and the coating of sensitive substrates.

Electron Deposition Technique

One of the significant drawbacks of traditional thermal evaporation is that it uses radiative heating, limiting the maximum evaporation temperature. Certain metals, such as tungsten, ruthenium, and niobium, have high melting points, low vapour pressures, and large bond energies between atoms, making them difficult to vaporise in a traditional thermal evaporation process.

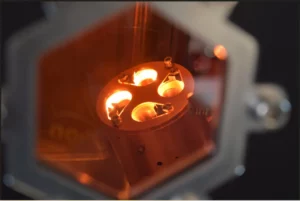

Electron-beam evaporation alleviates this issue by using a direct, high-energy electron beam that heats the target material directly, without the need for a heating element. Not only does this allow for high material utilisation efficiency, but it also allows for a broader range of source materials.

Technical specifications

| TAU E-Beam features | TAU-S | TAU-4 |

|---|---|---|

| Pockets | 1 | 4 |

| Maximum Power | 250W (500 optional) | 250W (500 optional) |

| Flux Monitoring | Yes | Yes |

| Materials | Rods (max 4mm dia), 1cc Crucibles | Rods (max 4mm dia), 1cc Crucibles |

| Co-Evaporation | No | Yes |

| Cooling | Water (min 0.5l/min) | Water (min 0.5l/min) |