The AXIS Supra+ has complete automation of sample handling which sets it apart from any other spectrometer. Auto sample exchange at the end of an experiment allows continuous operation. It also means that once samples have been introduced into the spectrometer, it can be operated remotely. Data acquisition can be started and controlled from any geographical location, especially valuable with enforced remote working policies imposed post-pandemic.

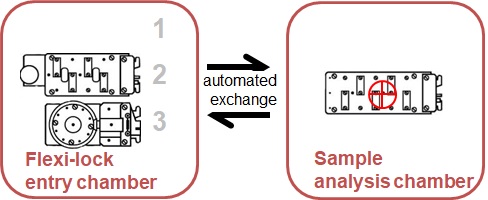

Three sample holders can be introduced into the AXIS Supra+ at a time, providing up to 7200 mm2 sample mounting area! That’s a lot of samples that can be mounted and analysed before there’s a requirement for manual intervention. With well managed sample loading it is possible to keep the spectrometer running 24/7, increasing instrument productivity.

Automation also includes the X-ray source and monochromator mirror so that calibration and switching between Al Kα and optional Ag Lα excitation sources is completely computer controlled. The motorised multi-position anode also ensures that optimised X-ray intensity is maintained between service intervals.

As expected from a fully automated instrument, gas handling required for both the Minibeam 4, monatomic Ar+ ion source or the multi-mode Minibeam 6 Arn+ gas cluster ion source is taken care of by a combination of software and hardware. Routine sample cleaning or more complex cluster depth profiling with sample rotation can be run with ease. Gas handling also extends to unattended operation of the He-discharge lamp for ultraviolet photoemission spectroscopy.

Unprecedented levels of automation also include routine maintenance aspects such as computer controlled bake-out and subsequent degassing of filaments.